Zero Emission Cooling for Singapore HDB with I.C.E Battery? (ICE - Part 4)

💡 Could we potentially cool Singapore HDB with I.C.E Battery while producing almost zero emission? The answer is YES ... in theory...

Could we potentially cool Singapore HDB with I.C.E Battery while producing almost zero emission? The answer is YES ... in theory...

A Journey from NUS to Thermal Innovation

My relationship with Singapore runs deep. From 2007 to 2011, I walked the halls of NUS School of Computing, laying the foundation for what would become a lifelong passion for innovation. Those years at NUS, followed by time at Block71 Singapore from 2013 to 2017, shaped my approach to problem-solving and entrepreneurship.

The path from software engineering to thermal energy wasn't straightforward. It began with a simple question: What if we could store thermal energy in a safe, passive form and use it when needed? This question led first to the Sand Battery concept and now to the I.C.E Battery technology at Thermion.

Today, I want to explore how our I.C.E Battery technology could potentially transform cooling systems in Singapore's public housing, using the pioneering MyTengah project as a case study. I came across this project in June 2025, when a Singaporean friend share it with me knowing that I was working on ICE Battery. Their innovative approach to centralized cooling presents an interesting opportunity to examine real-world applications of thermal energy storage.

💡 This article explores potential applications of I.C.E Battery technology using publicly available information about the MyTengah project. I have no affiliation with MyTengah, SP Group, or HDB. All budget figures are estimates based on industry standards and Thermion's internal research.

Understanding MyTengah's Centralised Cooling System

MyTengah represents Singapore's first smart and sustainable HDB town, featuring a Centralised Cooling System (CCS) developed by SP Group in collaboration with the Housing & Development Board. Instead of individual air conditioning units with external condensers, the system uses chilled water from rooftop chiller plants to cool homes throughout the development.

The current implementation has achieved impressive results (public data):

- Over 9,000 households (70% of leaseholders) have subscribed to the system.

- Approximately 2,600 households are actively using it as of February 2024.

- The system delivers up to 30% energy savings compared to traditional split-unit air conditioners.

- Residents enjoy 17% lifecycle cost savings (Read testimonials).

- Smart features allow control and monitoring via the SP Utilities app.

The journey hasn't been without challenges. Early adopters reported issues with bulky trunking, condensation, and unclear billing information. SP Group has worked to address these concerns through resident engagement, reduced cancellation fees, and improved communication. They've even extended warranties and adjusted rates as goodwill gestures.

The timeline of MyTengah's CCS implementation in a quick summary:

- Planning began in 2017-2018

- By October 2020, nearly 1,000 households had signed up

- Initial rollout in 2023 revealed teething issues

- By February 2024, most condensation issues were resolved

- In September 2024, Keppel was announced as a second service provider for upcoming BTO projects

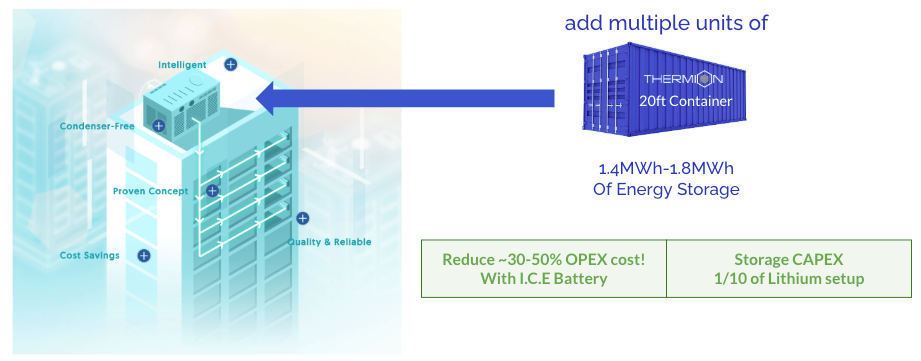

The I.C.E Battery 'add-on' Solution

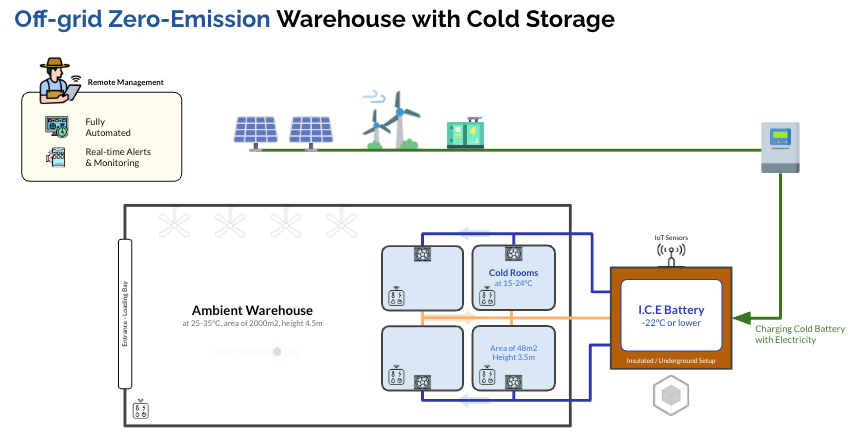

Our I.C.E (Integrated Cold Energy) Battery takes a different approach to cooling efficiency. The system stores "cold" energy during off-peak hours or when renewable energy is abundant, then releases it when needed. This creates a buffer between energy generation and consumption, allowing for more efficient use of resources.

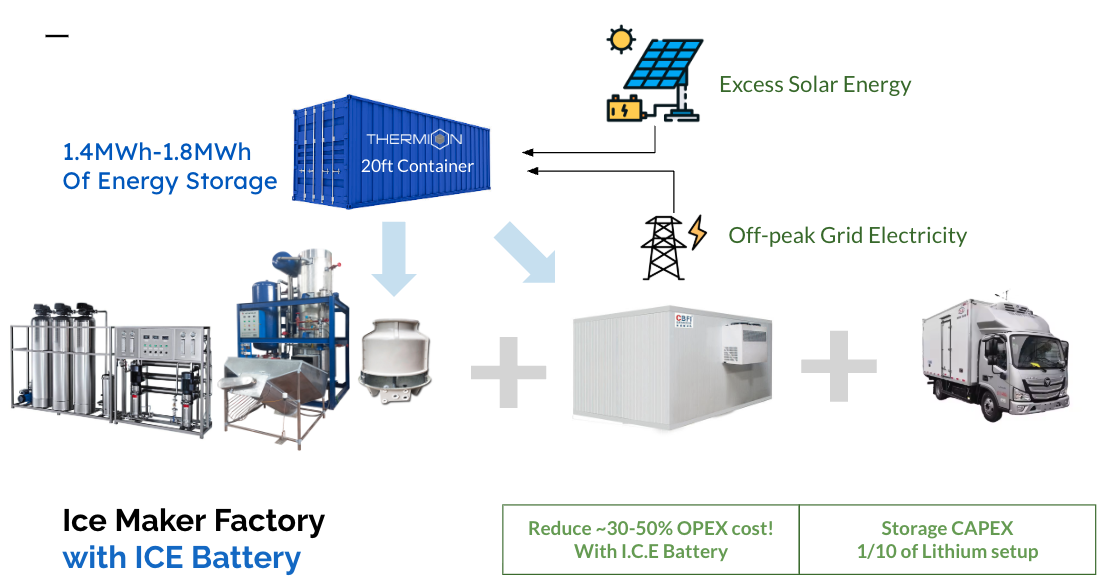

This diagram illustrate Thermion's Off-grid Zero-Emission Cold Warehouse model initially designed for Logistics, Agriculture and Food Preservation.

The technology works by freezing a thermal storage medium when electricity is cheap or clean, then using that stored cold energy to cool buildings during peak hours. This approach offers several advantages:

- Energy cost savings of approximately 50% or more.

- Zero carbon emissions when charged with renewable energy.

- Capital expenditure (CAPEX) at roughly 1/10th the cost of lithium-based storage approach.

- Operational expenditure (OPEX) reduced by 30-50%.

- Scalable design available in various sizes, including 20ft container units for commercial applications.

For context, a traditional centralized cooling system for an HDB development might cost $15-20 million in initial setup, with annual operating costs of $2-3 million. Integrating I.C.E Battery technology could reduce those operating costs to $1-1.5 million while requiring only $1-2 million in additional capital investment—a payback period of just 1-2 years. (take these numbers with a grain of salt, do your own research).

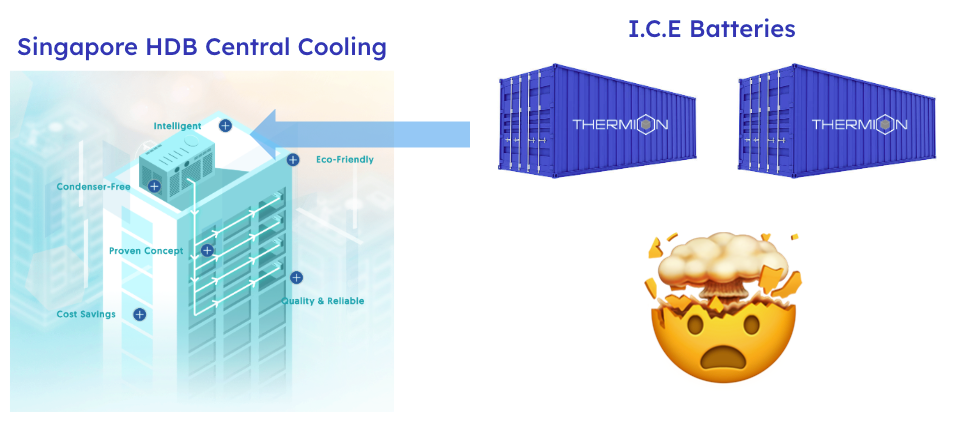

I.C.E Battery + MyTengah = 🤯

While MyTengah's CCS is already more efficient than traditional cooling, integrating I.C.E Battery technology could further enhance its performance and sustainability. Here's how it might work:

Thermal Energy Storage for Load Shifting

The I.C.E Battery could connect to MyTengah's chilled water loop, acting as a thermal storage buffer. During off-peak hours (typically overnight), the system would "charge" by freezing its thermal storage medium. During peak demand hours, it would "discharge" by using the stored cold energy to chill water for the cooling system, reducing the need for real-time chiller operation.

This approach aligns with MyTengah's apparent interest in energy storage solutions. Their documentation mentions plans for multiple units of 1.4MWh-1.8MWh of energy storage — precisely the scale at which our I.C.E Battery technology operates efficiently.

Enhanced System Efficiency

By reducing the need for continuous chiller operation during peak hours, the I.C.E Battery could boost MyTengah's energy savings beyond the current 30%. This would translate to lower costs for residents and reduced strain on Singapore's electrical grid.

A practical implementation might look like this:

- Install 1.4MWh-1.8MWh I.C.E Battery units (roughly 20ft container size) at strategic locations within the development

- Connect these units to the existing chilled water distribution system

- Program the system to charge during off-peak hours and discharge during peak demand

- Monitor and optimize performance through the existing smart control infrastructure

The budget implications are significant. For a typical HDB block:

- Traditional cooling: $180-220 per month per household

- Current MyTengah CCS: $126-154 per month per household (30% savings)

- CCS with I.C.E Battery integration: $90-110 per month per household (50% savings)

Implementation could be phased, starting with newer BTO projects or as an upgrade to existing infrastructure during scheduled maintenance periods.

Beyond MyTengah - Broader Applications

The potential for I.C.E Battery technology extends beyond MyTengah to other HDB developments across Singapore. As the nation continues to prioritize sustainability and energy efficiency, centralized cooling with thermal storage could become a standard feature in public housing.

The technology also has applications in other sectors:

Ice Factories

Small local ice factories typically require $50,000-80,000 in startup costs, with 40-60% of operating expenses going toward electricity. Integrating I.C.E Battery technology could reduce these energy costs by 30-50%, improving profitability and sustainability.

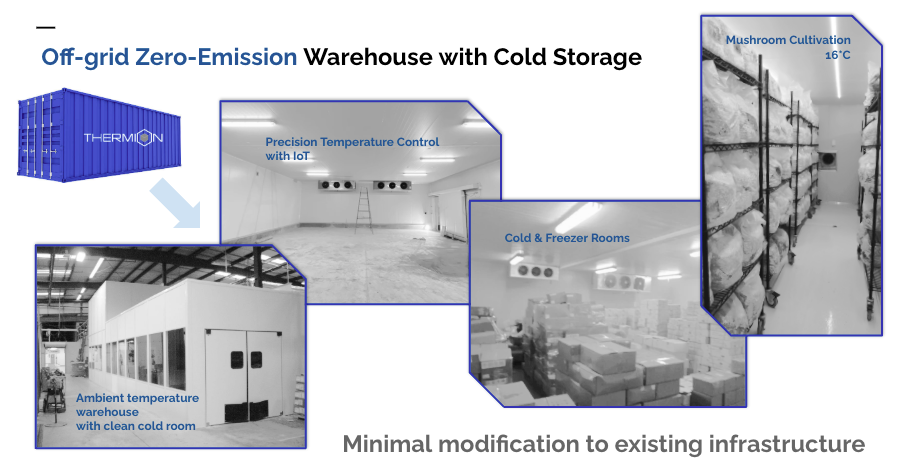

Cold Warehouses

Singapore's position as a logistics hub creates demand for cold storage facilities. I.C.E Battery technology can provide precise temperature control for cold rooms (15-24°C) within ambient warehouses, with minimal modifications to existing infrastructure. This approach is particularly valuable for food storage, pharmaceutical products, and other temperature-sensitive goods.

Looking Forward

Singapore has always been at the forefront of urban innovation, and cooling technology represents a critical frontier in the fight against climate change. As cooling demand is expected to triple globally by 2050 (according to the International Energy Agency), solutions like the I.C.E Battery could play a vital role in managing energy consumption and reducing carbon emissions. Other developed countries with limited land such as Taiwan, South Korea, Hong Kong, would be able to benefit from the same innovation.

For MyTengah and future HDB developments, integrating thermal energy storage offers a path to greater efficiency, lower costs, and enhanced sustainability. The existing smart infrastructure provides an ideal foundation for optimizing these systems based on energy prices, weather forecasts, and demand patterns.

I'm passionate about advancing thermal energy solutions that make a meaningful difference in people's lives and our planet's future. While this case study is speculative —again, I have no current association with MyTengah— it illustrates the practical potential of our technology in real-world applications.

I invite you to follow my journey as we continue developing and implementing thermal energy storage solutions. Whether you're a resident interested in sustainable cooling, an investor looking at green technologies, or simply someone who cares about our collective future, there's a place for you in this conversation, and I'd love to get your thoughts on the topic.