I.C.E. Battery Cooling: The Science and Savings (ICE - Part 2)

The I.C.E. Battery represents a fundamental shift in how we approach cooling. By storing cold energy efficiently and delivering it passively, we can decouple cooling demand from peak energy generation, slash carbon emissions, and reduce operational costs.

Now, let's dive deeper. How exactly does this technology work? How does it store cold, and more importantly, how does it deliver cooling efficiently and sustainably? In this post, we'll break down the core principles behind the I.C.E. Battery and explore the significant benefits it offers.

The Core Principle: It's all about Removing Heat

First, let's clarify what we mean by "storing cold." Technically, you can't store "cold" itself, as cold is simply the absence of heat energy. What the I.C.E. Battery actually does is use energy to remove a large amount of heat from a specialized thermal storage material, lowering its temperature dramatically — often to -22°C (-7.6°F) or even colder.

Think of it like pumping water uphill to store potential energy. We use electrical energy to "pump" heat out of the storage material, creating a reservoir of low-temperature potential energy. This stored potential can then be tapped later to absorb heat from its surroundings, providing a cooling effect.

The materials used for this thermal storage are carefully selected for their ability to hold these low temperatures efficiently and safely over long periods, using substances that are abundant and environmentally friendly.

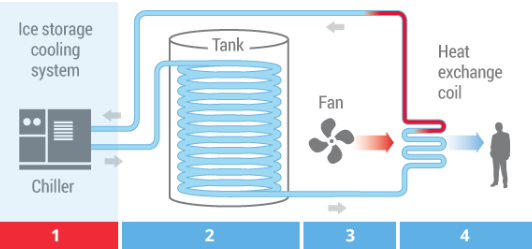

Charging the I.C.E. Battery: The Big Chill

The "charging" phase is where the I.C.E. Battery gets cold. During this process, electrical energy powers a highly efficient system designed to extract heat from the battery's core.

This electricity can come from various sources:

- Renewable Energy: Ideally, solar panels or wind turbines provide zero-emission power, we can definitely store the excess renewable energy in ICE Battery.

- Off-Peak Grid Power: We can also charged overnight when grid electricity is often cheaper and demand is lower, helping to balance the grid. On-top of that charging at night might be more efficient due to cooler environment temperature.

The charging system works intensively to lower the temperature of the internal storage material down to its target operating point (-22°C). Once charged, the battery is ready to deliver cooling, and the primary energy input phase is complete.

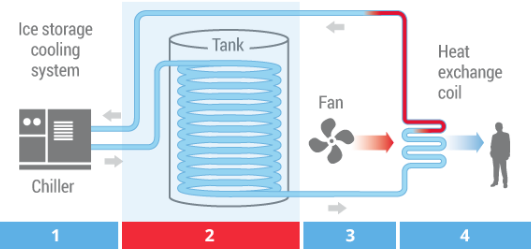

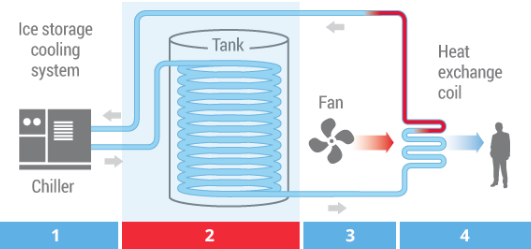

Discharging: Delivering Cooling Passively

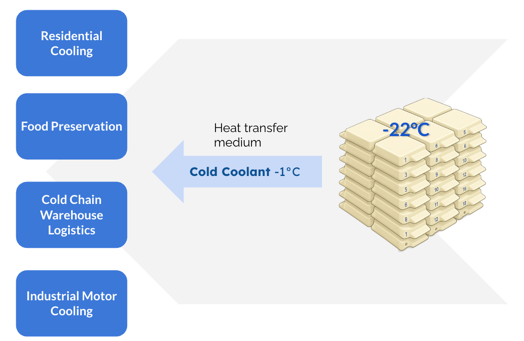

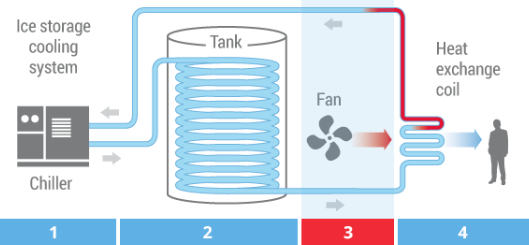

This is where the magic happens. When cooling is required, the I.C.E. Battery enters its discharge phase. A heat transfer medium — this could be air for direct space cooling or a liquid coolant for refrigeration or HVAC systems — is circulated through a heat exchanger integrated with the cold storage core.

As the warmer medium passes through the heat exchanger, it transfers its heat to the extremely cold storage material. The storage material absorbs this heat, causing the heat transfer medium to become significantly chilled (e.g., producing air or coolant potentially near or below freezing, like -1°C as mentioned in our concepts).

This chilled air or coolant is then directed to where the cooling is needed — a well insulated warehouse, a residential living space, or an industrial process. The key here is that the core cooling process during discharge is largely passive. While auxiliary components like small fans or pumps might be needed to circulate the heat transfer medium, the main thermal work (absorbing heat) doesn't require continuous high-power electricity consumption, unlike a traditional air conditioner compressor.

Key Components (A Simplified Look)

While the specific design can vary based on application, a typical I.C.E. Battery system includes several core components:

- Thermal Storage Core: The insulated heart of the battery containing the specialized cold storage material.

- High-Performance Insulation: Crucial for maintaining the extremely low temperatures for extended periods (days, potentially) with minimal energy loss.

- Charging System Interface: Connects to the power source and the mechanism that actively removes heat during the charging cycle.

- Discharge System Interface: Includes heat exchangers that allow efficient transfer of "cold" (i.e., heat absorption) to the air or liquid coolant during the discharge cycle.

- Control System & IoT: Smart controls manage the charging/discharging cycles, monitor temperatures, and allow for remote management and automation, ensuring optimal performance and efficiency.

The Benefits: Why I.C.E. Battery Technology is a Game-Changer

The way the I.C.E. Battery operates translates into substantial real-world advantages:

- Massive Cost Savings: By charging using cheaper off-peak electricity or free renewable energy, and discharging passively, users can achieve significant savings on their energy bills — our projections show potential savings of approximately 50% or more compared to conventional cooling methods.

- Drastic Carbon Emission Reduction: When charged with renewables, the I.C.E. Battery enables near-zero-emission cooling. Even when using grid power, shifting consumption to off-peak hours (often when the grid mix is cleaner) can lead to >90% reduction in associated carbon emissions compared to peak-hour conventional cooling.

- Energy Independence & Grid Stability: Perfect for off-grid locations or areas with unreliable power. For grid-connected users, it reduces strain during peak demand periods, contributing to overall grid stability.

- Reliability and Potential Longevity: Thermal batteries generally have fewer moving parts than complex refrigeration cycles and may offer a longer operational lifespan with less performance degradation over time.

- Versatility: As highlighted in Part 1, the technology is adaptable to a wide array of needs, from large industrial warehouses requiring precise temperatures (like for mushroom cultivation) down to potential future portable consumer units.

- Safety and Sustainability: Utilizes environmentally benign materials, avoiding the hazardous substances or high global warming potential refrigerants found in some traditional systems.

I.C.E. Battery vs. Conventional Cooling

Compared to traditional air conditioning or refrigeration, the I.C.E. Battery offers key differences:

- Energy Source Flexibility: Can leverage renewables and off-peak power effectively.

- Passive Cooling Delivery: Reduces electricity consumption significantly during cooling operation.

- Environmental Impact: Dramatically lower carbon footprint and use of safer materials.

- Lifetime Cost: Potential for lower overall cost due to energy savings and potentially longer lifespan.

The Future is Cool (and Sustainable)

The I.C.E. Battery represents a fundamental shift in how we approach cooling. By storing cold energy efficiently and delivering it passively, we can decouple cooling demand from peak energy generation, slash carbon emissions, and reduce operational costs.

I believe this technology is crucial for building a sustainable future where essential cooling is accessible, affordable, and environmentally responsible.

In the upcoming parts of this series, we'll explore specific applications of the I.C.E. Battery in more detail, showcasing real-world examples and diving deeper into the technical nuances. Stay tuned, follow Thermion's journey, and let's build a cooler, greener future together!