The "Sand Battery" Patent USPTO 12-130086-B1 (SAND - Part 7)

Full content of USPTO 12-130086-B1: Thermal Storage Batteries and Thermal Storage Battery Systems for Drying Agriculture and Food Products, aka the Sand Battery.

Let's dive deep into the actual content of US Patent for this "Sand Battery" and let me simplify that for you.

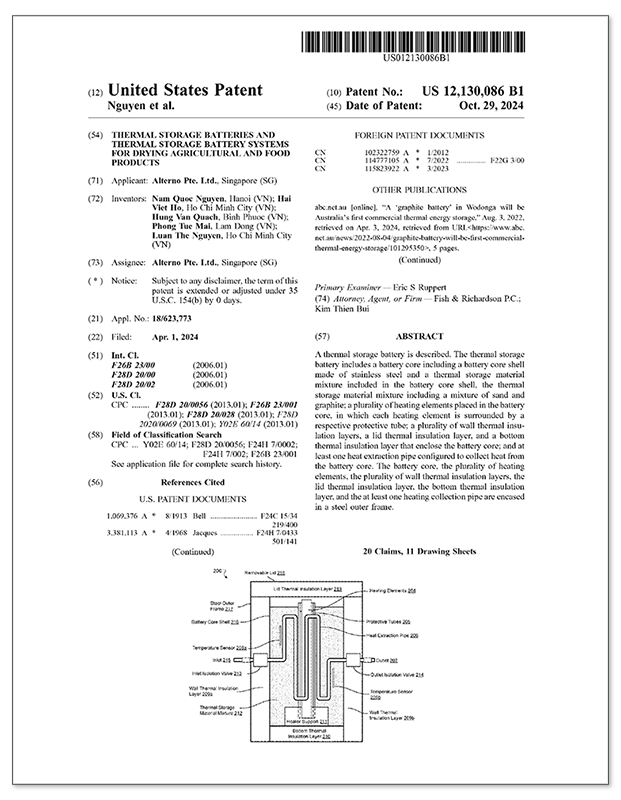

After two years of intensive research, development, and refinement, I'm thrilled to announce that our Sand Battery technology has received official recognition from the United States Patent and Trademark Office (USPTO). On October 29, 2024, patent US 12,130,086 B1 for "Thermal Storage Batteries and Thermal Storage Battery Systems for Drying Agricultural and Food Products" was approved, validating our pioneering work in thermal energy storage.

As one of the first, if not the first, in Southeast Asia to commercialize this novel form of energy storage, we've established a foundation for sustainable thermal solutions that can transform multiple industries.

🏔️ The Patent Journey

The path to patent approval began with my initial prototype in late 2022, later evolving through multiple iterations and rigorous testing in various labs, we moved twice. The formal application process started with our Vietnamese Patent Application No. 1-2023-05430, filed on August 15, 2023, which served as the priority document for our USPTO application filed on April 1, 2024.

Securing this patent is significant not just for our team but for the broader field of renewable energy storage. It validates that our approach to thermal energy storage offers unique advantages and innovations that distinguish it from existing technologies. The patent provides a framework for further development and commercialization, potentially opening doors to partnerships and implementations across various sectors.

Let me highlight the 3 key design consideration in the Patent using simple language:

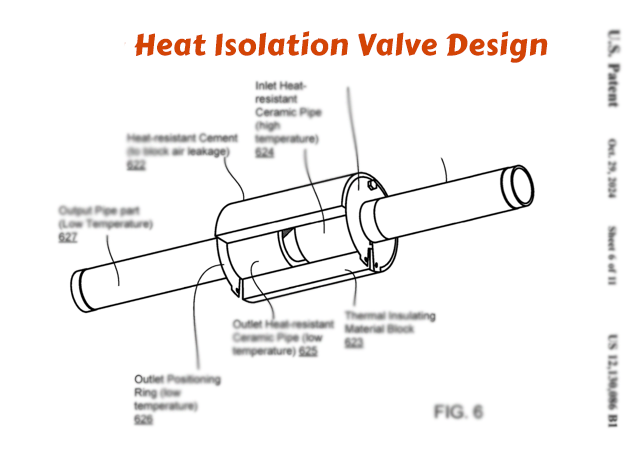

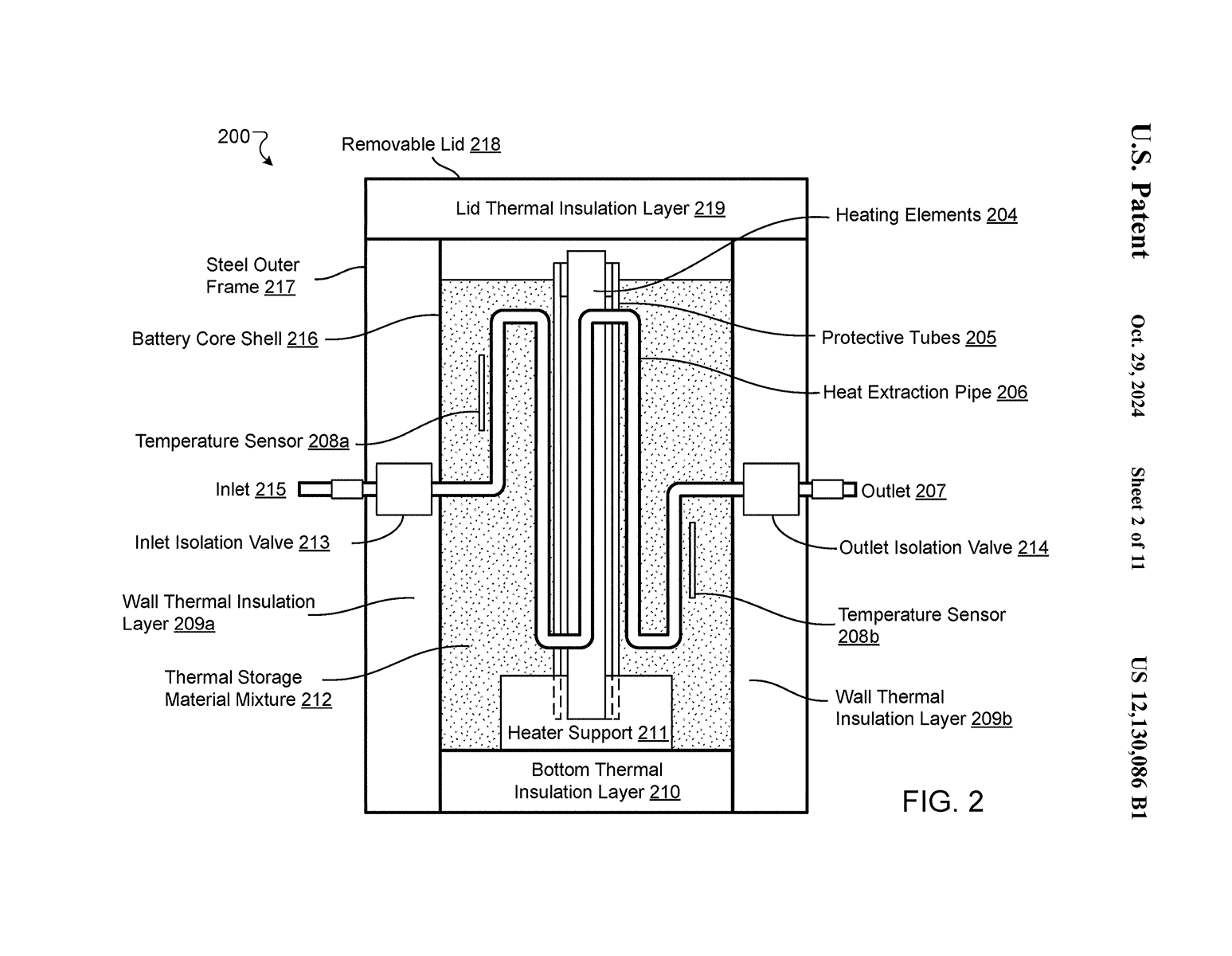

1 - Heat Isolation Valve Design

One of the most critical innovations in this Thermal Battery design is the heat isolation valve system. In layman's terms, these isolation valves are fixed structural components designed to minimize thermal transfer between connecting pipes.

Conventional thermal storage systems often suffer from heat leakage through metal-to-metal connections, our patented design incorporates specialized isolation structures that reduce thermal bridging. These fixed components create thermal breaks in the system, preventing unwanted heat transfer through the metal pipes themselves.

The inlet isolation valve and outlet isolation valve are strategically positioned to minimize heat loss at critical junction points in the system. By reducing metal-to-metal thermal conductivity, these fixed structures ensure that thermal energy remains contained within the battery core rather than being lost through the connecting pipework.

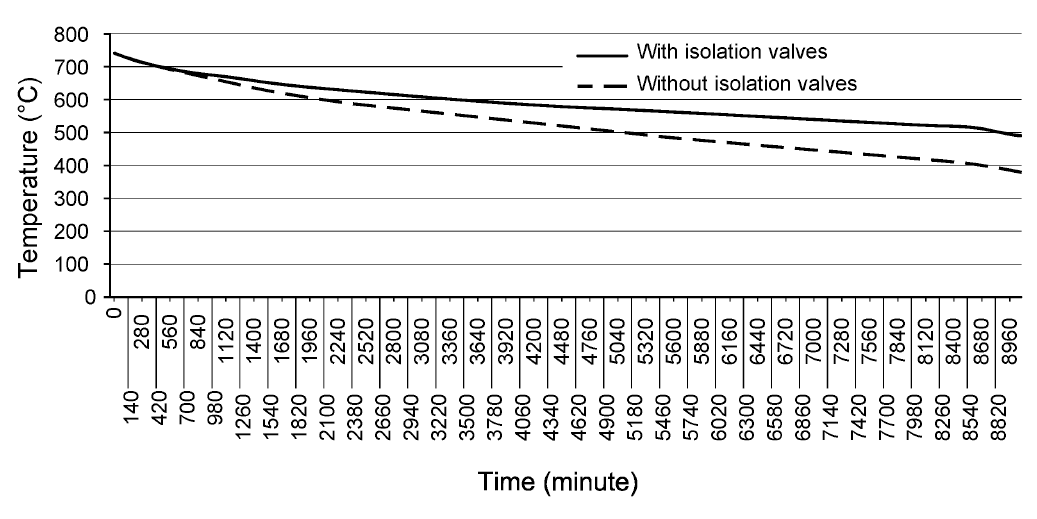

In effect, this translates to longer heat retention times, more predictable performance, and ultimately greater energy savings. A thermal storage system might lose significant heat through poorly insulated pipe connections, but our design maintains thermal integrity even during extended storage periods.

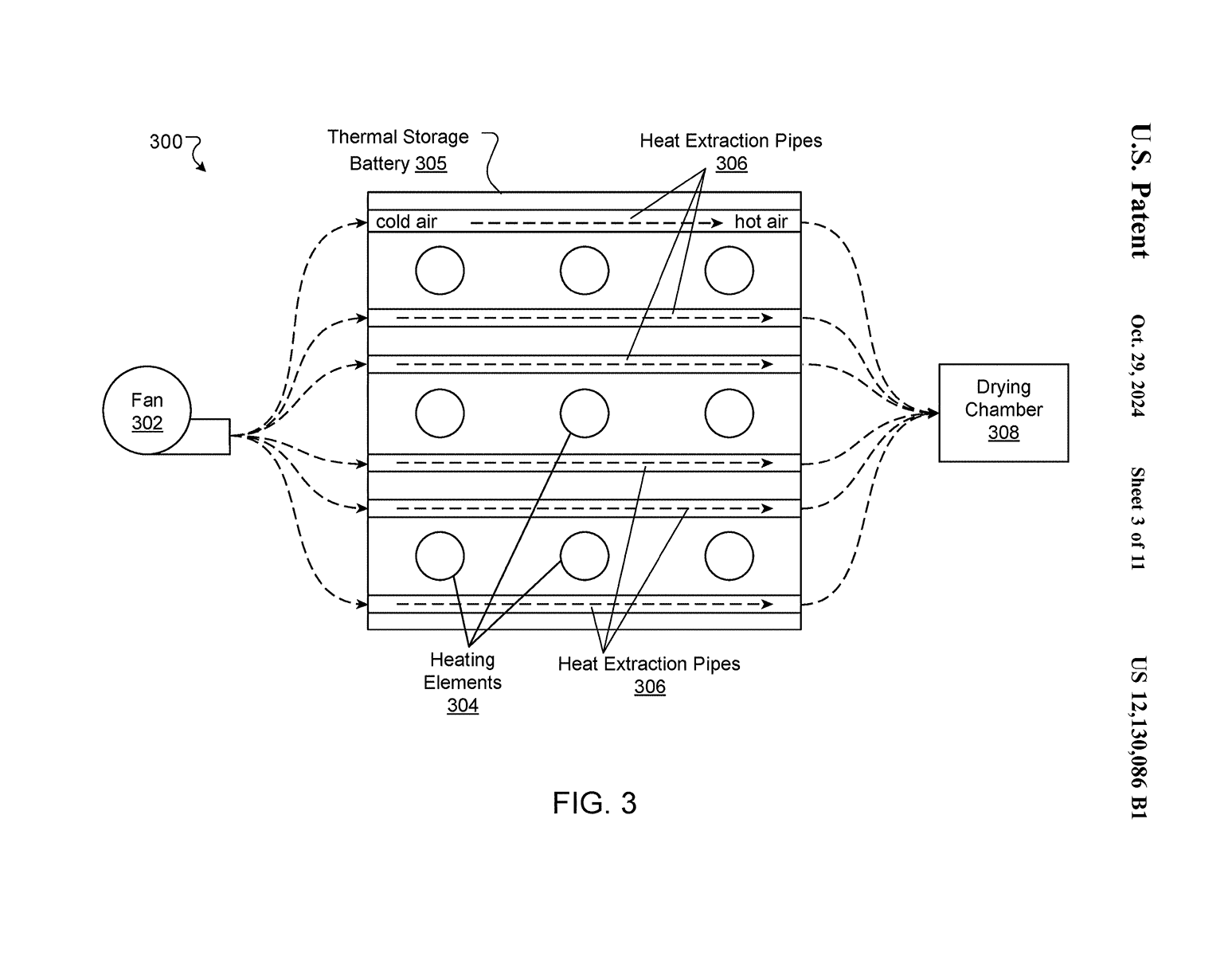

2 - Distribution of Heating Elements

Another key innovation in our Sand Battery design is the strategic distribution of heating elements throughout the thermal storage material. Rather than using a single, large heating element, our patent describes a plurality of heating elements (204) placed throughout the battery core, each surrounded by a protective tube (205).These protective tubes are made from a specialized carbon-based mixture of silicon carbide and graphite, materials chosen for their exceptional heat conductivity and structural integrity at high temperatures. This design serves multiple critical functions:

- Even Heat Distribution: By dispersing multiple heating elements throughout the thermal storage material, we ensure uniform heating without hot spots or cold zones.

- Rapid Charging: The distributed elements allow for faster heat transfer to the storage medium, reducing charging time compared to centralized heating approaches.

- Redundancy and Reliability: If one heating element fails, the others continue functioning, preventing complete system failure.

- Optimized Heat Transfer: The protective tubes enhance heat conduction to the surrounding sand-graphite mixture while protecting the heating elements from direct contact with the storage material.

This distributed heating approach is particularly important for agricultural applications, where consistent and reliable heat delivery can make the difference between properly dried products and spoilage.

3 - Insulation Layer System

Perhaps the most visually distinctive aspect of our Sand Battery design is its size as very thick insulation layer all around. The patent details a specific arrangement of thermal barriers that work together to minimize heat loss:

- Wall Thermal Insulation Layers: Multiple layers of high-performance insulation materials surround the battery core shell, creating a thermal barrier that significantly reduces heat transfer to the external environment.

- Lid Thermal Insulation Layer: The removable lid includes dedicated insulation to prevent heat from escaping through the top of the battery, this layer is even thicker than the rest because Heat always rises up. It is the most vulnerable part of any thermal storage system.

- Bottom Thermal Insulation Layer: A specialized insulation layer made of similar material as the wall though not as thick, beneath the battery core prevents heat from being lost to the ground or supporting structure.

In thermal storage, inadequate insulation can result in 30-50% heat loss within 24 hours. Our multi-layer approach reduces this to just 5-10% loss per day, allowing for extended storage periods without significant energy degradation.

After all, it translates directly to cost savings and reliability. A well-insulated Thermal Battery using Sand as storage medium can maintain usable heat for days rather than hours, providing a buffer against intermittent renewable energy availability and ensuring consistent heat supply for agricultural drying processes.

🔥 Real-World Applications

While the technical innovations are impressive in their own right, what truly matters is how they translate to real-world benefits. Our patent specifically addresses applications in drying agricultural and food products, an energy-intensive process that impacts billions of people worldwide.

Traditional drying methods often rely on burning wood, coal, or fossil fuels, contributing to deforestation and carbon emissions globally, but that's the only choice most of us humans are taught. Alternatively, farmers depend on direct sunlight, which is unreliable and weather-dependent.

A Thermal Energy Storage system offers a third path: storing excess renewable energy as heat and delivering it consistently when needed.

For a coffee farmer in Vietnam's Central Highlands, this means being able to dry beans to precise moisture levels regardless of weather conditions, using solar energy captured during peak production hours. For a tea processor, it means consistent quality without the environmental impact of wood-fired dryers.

The patent also highlights how our system addresses limitations of electrochemical batteries, which involve costly and environmentally problematic materials like lithium and cobalt. Sand and graphite, by contrast, are abundant, inexpensive, and environmentally benign materials with minimal processing requirements.

🫡 Looking Forward

The USPTO patent approval represents both validation of our past work and a foundation for future innovation.

I'm particularly excited about the potential for adapting this technology to residential heating, industrial processes, and even grid-scale thermal storage. The core principles of this Thermal Battery system can be applied and scaled across numerous contexts.

This patent is just a milestone in the journey. As we continue to refine and expand the technology, we remain committed to developing sustainable energy solutions that address real-world challenges.

I welcome inquiries from potential collaborators, implementers, and fellow innovators who share our vision for Zero-Emission Thermal Energy Storage solutions.

Behind this achievement, lies a mysterious timing of events leading to the approval and discovery of this Patent, continue reading in Part 8.